Interferometry & Reflectometry

Measure silicone layer thickness and distribution

Glide into stability studies

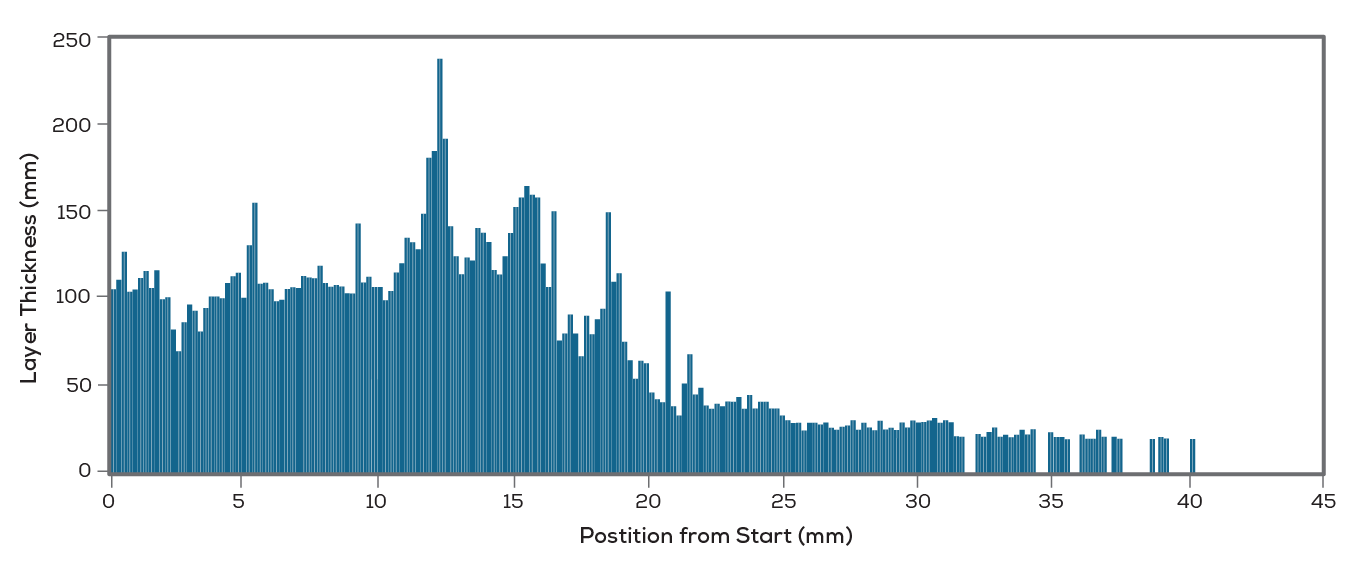

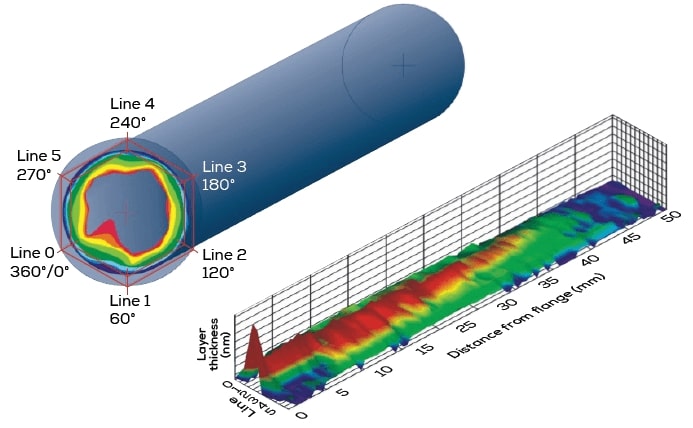

Silicone is essential for putting the “delivery” into drug delivery when we’re talking about syringes and cartridges for auto injector devices. An even coating at the right thickness can ensure smooth delivery within the specified tolerances for glide force. But storage over time can cause the distribution of the silicone coating to be altered, resulting in thin patches that cause the device to jam or stop up. Obtaining quick and accurate measurements of the thickness of the silicone film over the entire length of the device and at multiple time points can provide critical information for stability and formulation studies.

Get the skinny on how to measure thin film thickness

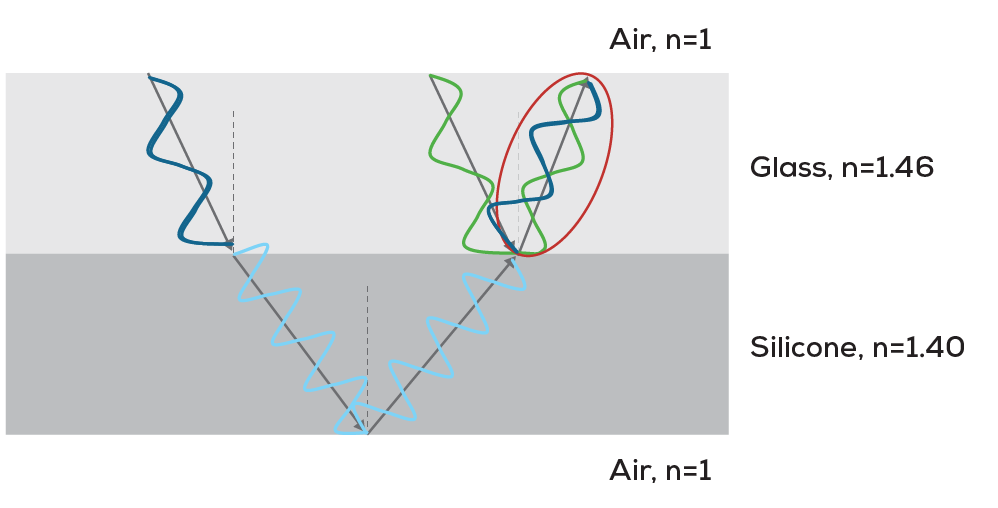

Laser interferometry and white light reflectometry both use the wavelike property of light to map out the surface topography, and therefore the thickness, of the silicone film, but vary slightly in the type of light that is projected.

Light it up with white light

With white light reflectometry, white light is directed at the sample and the reflected light is detected.

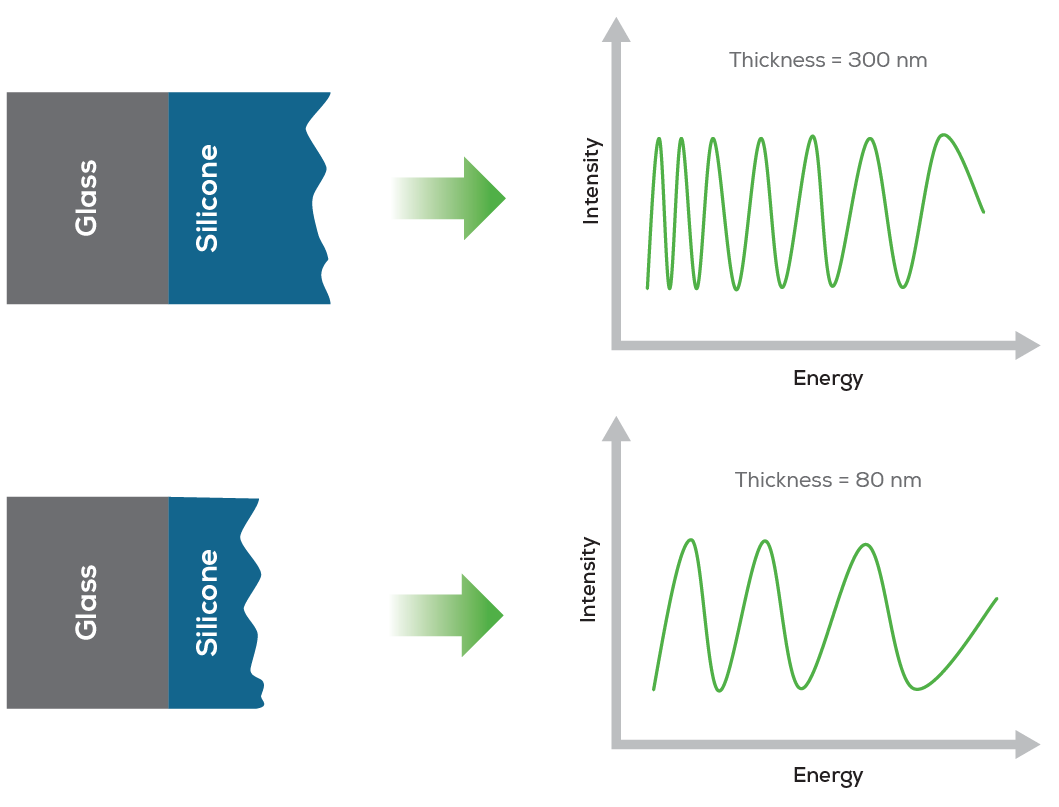

The light interacts differently with glass and silicone, causing constructive and destructive interference in the reflected light.

The changes to the reflected light are proportional to the thickness of the silicone film, enabling highly accurate measurement down to 80 nm.

Light is reflected off of the test material

Silicone alters reflected light

Blast it with laser light

To measure thinner films, you need a more coherent light source. Laser interferometry uses a similar principle as white light reflectometry, but with a laser to deliver thickness measurements between 20 and 80 nm.

Repeating this process by moving the device produces a silicone coating profile

Taking the reflectometry measurements at discrete points, coupled with moving along the device and rotating it, creates a profile of the silicone thickness throughout a device.

Bouncer

Wonky silicone coatings for injectable devices can jam them up or ooze oil into your drug. Bouncer makes it easy to find out if the coating’s too thick, too thin or good to go. Quantitative measurements on silicone layer thickness and distribution let you find the sweet spot for your device.

Ready for more?

Biopharma scientists can now use the right tool for silicone film measurement with an instrument that combines white light reflectometry and laser interferometry. Have a question or ready to find out more?